Steam Turbines for Thermal Power Plants (Up to 250 MW)

Characteristics

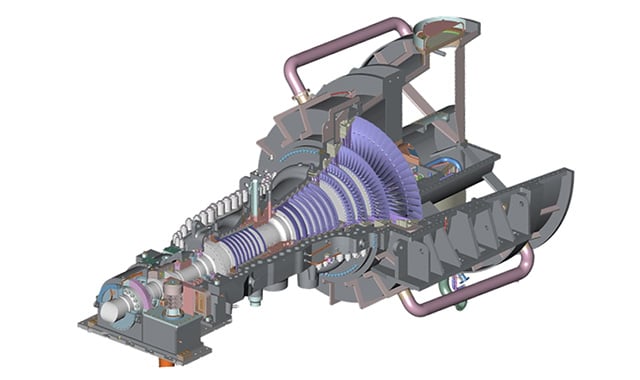

Exhaust steam exits the turbine from only one direction (single-flow). By utilizing a longer last stage blade (LSB), a single flow turbine with axial exhaust is possible in comparison to a double-flow turbine with downward exhaust. An axial exhaust reduces hood losses, thus allowing higher efficiency to be achieved as compared to a downward exhaust.

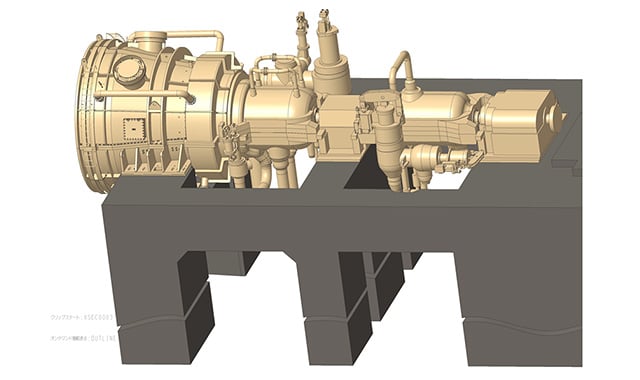

In addition, as a single welded (or mono-block) rotor is used, the high pressure (HP), intermediate pressure (IP) and low pressure (LP) sections can be contained within a single casing. This compact frame turbine (SRT) can reduce construction costs for the turbine building and foundation. A smaller number of components also reduce the time required for inspections and number of spare parts, thus allowing easier maintenance.

Two Casing Turbine

(HP Turbine - IP/LP Turbine)

Single Casing (SRT) Turbine

(HP/IP/LP Turbine)

Steam Turbine Specifications

| No. of casings | Single casing (HP/IP/LP Turbine) Double casing (HP/IP Turbine - LP Turbine) Double casing (HP Turbine - IP/LP Turbine) |

|---|---|

| Output | Up to 250 MW |

| Main steam conditions | Up to 16.5 MPa / Up to 600°C |

| Reheat steam conditions | Up to 600°C |

| Revolutions per minute | 3,000 min-1 (50 Hz) / 3,600 min-1 (60 Hz) |

- Downward exhaust can also be designed if the customer has such requirements.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation / DIASYS Netmation4S

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- DIASYS Solutions

- Energy Storage

- Fuel Cells

- Others

- Catalogue

- HIACS Series

- Technical Report