Compact Process Station (CPS)

Overview

The DIASYS Netmation Compact Process Station (CPS) is a piece of control equipment that can be used for control operation and site ON/OFF control, and can be mounted on a DIN rail.

Unlike a Multiple Process Station (MPS), a CPU chassis is not required, and a CPS supports both single and duplex configurations. This compact unit is suitable for small-scale systems such as facility management systems and package boilers.

Functions of the Compact Process Station (CPS)

Retaining the Features of a DCS while Offering the Same Price and Size as a PLC

A programmable logic controller (PLC) is not functional enough-

but a distributed control system (DCS) is too big-

To cater to this kind of request, Mitsubishi Power has developed the Compact Process Station (CPS), retaining the features of DIASYS Netmation in the small form factor of a PLC (sequencer).

The CPS can be connected in the same manner as an MPS: it supports monitoring from an Operator Station (OPS), maintenance from an Engineering & Maintenance Station (EMS), updating of control logic and even data log collection from an Accessory Station (ACS).

Flexible System Configurations Tailored to Users' Needs

You can easily add I/O modules to a CPS as needed.

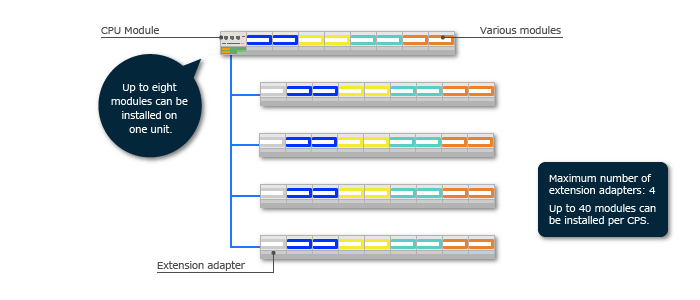

By using an extension adapter for each CPS unit, up to 40 modules can be used.

In addition, as modules are connected through FLEX I/O communication interfaces from AllenBradley, in addition to DIASYS Netmation I/O modules, modules from Rockwell Automation can also be used.

Up to eight modules can be installed on a single unit.

Maximum number of extension adapters: 4

Up to 40 modules can be installed per CPS

Should a module fail, it can be replaced while the power is on (as with an MPS), reducing facility downtime.

Card Module Lineup

Check the following pages for information about our lineup of CPS modules.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation / DIASYS Netmation4S

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- DIASYS Solutions

- Energy Storage

- Fuel Cells

- Others

- Catalogue

- HIACS Series

- Technical Report