Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

Overview

A gas turbine burns fuel to rotate the turbine. Excessive fluctuation of pressure (combustion vibration) inside a combustion chamber during combustion can damage the combustion chamber and turbine parts. This is why it is so important to suppress combustion vibration.

Mitsubishi Power offers A-CPFM and CPFM systems to suppress combustion vibration and contribute to increasing the reliability and availability of gas turbines. Recently, the performance of gas turbines has been improved due to increasing operating temperatures, and the factors contributing to compositional changes of liquefied natural gas (LNG) that increase combustion vibration have also increased. This has resulted in heightened expectations for hydrogen fueling for decarbonization directed at A-CPFM and CPFM.

Features

Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM)

- An advanced combustion pressure fluctuation monitoring system (A-CPFM) automatically suppresses combustion vibration during combustion.

The relationship between combustion vibration and the operational parameters that can affect combustion vibration are modeled by this system. When combustion vibration occurs, it is suppressed by adjusting those operational parameters automatically using this model.

-

A-CPFM Screen Shot

Combustion Pressure Fluctuation Monitoring System (CPFM)

A combustion pressure fluctuation monitoring system (CPFM) is a protection device for a gas turbine.

If severe combustion vibration that even an A-CPFM cannot suppress occurs, a CPFM automatically reduces power generation of the gas turbine or stops the gas turbine completely to avoid damage to the gas turbine.

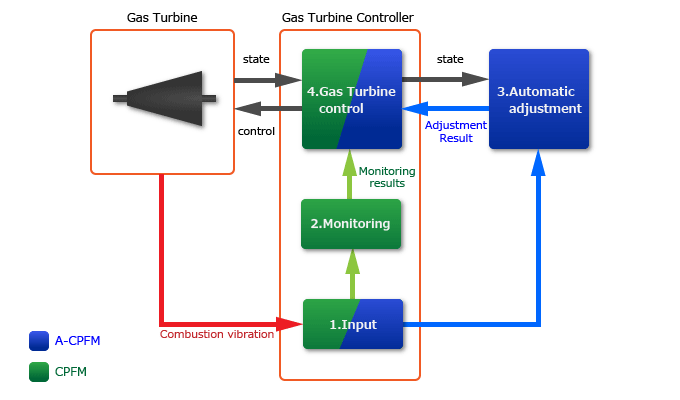

System Configuration & Processing Flow

- Combustion vibration is processed by a dedicated input device, and then sent to the monitoring processes of the CPFM and the automatic adjustment processes of the A-CPFM.

- Based on the combustion vibration strength sent from the input devices, the monitoring process of the CPFM generates a monitoring result (No problem, Reduce power generation, or Stop the gas turbine) which is sent to the gas turbine control process.

- In the automatic adjustment process of the A-CPFM, based on the combustion vibration strength sent from the input device and the status of the gas turbine sent from the gas turbine control process, an adjustment result is determined and sent to the gas turbine processing unit.

- The gas turbine control process controls the gas turbine based on the monitoring result sent from the monitoring processes of the CPFM and the adjustment result sent from the automatic adjustment processes of the A-CPFM.

Products

- GTCC

- Steam Power

- IGCC

- Geothermal

-

Gas Turbines

- Product Lineup

- Comparative Performance

-

Technical Information

- Gas Turbines for Mechanical Drive Applications

- Cutting-Edge Elemental Technology Producing 1600°C Class J Gas Turbines

- Development of High-Efficiency Gas Turbine Applying 1600°C Class J Technology

- Combustor Technologies Supporting Stable Operation

- Overview and Verification Status of T-Point 2 Demonstration Facility

- Comprehensive Efforts from Development to Manufacturing

- Summary of Orders

- Development History

- Product Selection Assistant (Middle & small Class)

- Aero-derivative Gas Turbines

- Steam Turbines

- Boilers

- Air Quality Control Systems (AQCS)

- Generators

-

Control Systems

- What is DIASYS?

- DIASYS Netmation / DIASYS Netmation4S

-

DIASYS Optional Products

- IR-S Infrared Flame Detector

- Net IR-S Infrared Flame Detector

- Rail Mounting Net IR-S

- Boiler Tube Leak Detector

- Shaft Vibration Analyzer

- Simulator

- Advanced Combustion Pressure Fluctuation Monitoring System (A-CPFM) / Combustion Pressure Fluctuation Monitoring System (CPFM)

- Multi-Coal Fired Boiler Optimum Control

- DIASYS Solutions

- Energy Storage

- Fuel Cells

- Others

- Catalogue

- HIACS Series

- Technical Report